New underground haulage solution

Mining isn’t just about the excavation of material. A significant cost is also tied up in haulage of the material. That’s a problem we now have a solution for, across both open pit and underground mining operations.

For many years, our software has addressed the haulage problem for open pit mines, however, with the release of Deswik.LHS for Underground, it now includes new functionality to calculate haulage for underground mining operations. The functionality is available as a technology preview in version 2017.2 of Deswik.Suite.

The complications of underground haulage

The issue of underground haulage is complicated by many factors. Those include tramming using a LHD (load, haul, dump machine) to a truck, rehandle in remuck bays, tipping into orepasses, shafts and backfill operations.

The payoffs

However, finding a solution to handle those issues, has great payoffs for operators. The results of an accurate haulage study can pre-emptively highlight issues with ventilation and congestion, as well as provide defendable haulage metrics for both costing and budgetary purposes.

Our solution

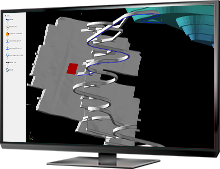

Our approach to solving the problem of underground haulage had to be as simple as possible and integrated into the current Deswik.Suite:

Our approach to solving the problem of underground haulage had to be as simple as possible and integrated into the current Deswik.Suite:

- The haulage network can be fed in from the design centerlines used as the data source, for scheduling in the suite.

- Some sites “trim” their intersections to prevent double accounting of tonnage. We’ve taken that into account and provided easy to use tools to re-extend the design centerlines, and there are a number of tools to regenerate the centerlines for as-built or completed development, should those centerlines exist.

- The entire process is presented in a compact, process-driven user interface that guides you through the process of generating the input data.

- The schedule source is integrated with Deswik.Sched, including the use of derived tasks for backfill. All results are then written back to Deswik.Sched, for single source reporting.

- With complex networks, it’s important the path is correct. Extensive auditing tools have been included to allow you to troubleshoot where material can flow from and to, as well as helping with the process of connecting your blocks to the network.

For more information on the Deswik.LHS for Underground solution, download the flyer or contact your nearest Deswik office.

Wayne Romer

Technical Director