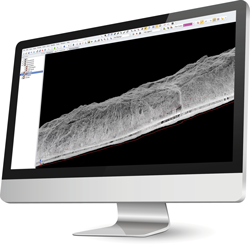

Generate quality survey solids from high-resolution scan data in less time

We’re pleased to announce the launch of our advanced survey module, Deswik.AdvSurvey – featured in the latest release of Deswik.Suite, version 2019.1.

Following on from the launch of our core survey functionality within Deswik.CAD, Deswik.AdvSurvey takes Deswik’s survey capability to the next level.

Designed to handle large amounts of scanned survey point data and automate the process of creating valid solids from it, Deswik.AdvSurvey is built to meet the changing scope of survey in mining.

Most sites are now using scanners and UAVs to complement their current survey methods. “They are using these tools to improve existing survey practices, and in many cases, they see both improved efficiency and increased safety by removing surveyors from operational areas in the field.” says Stephen Rowles, Deswik Product Manager for Survey.

The new technology focuses on efficiently generating two specific survey objects: a wireframe and an outline of the development. “Sometimes the point cloud can be quite clean but there is usually some obstruction, vent bag, services etc that need to be removed. We needed a way to take the scan points and generate a high-quality, clean wireframe and outline.

The new technology focuses on efficiently generating two specific survey objects: a wireframe and an outline of the development. “Sometimes the point cloud can be quite clean but there is usually some obstruction, vent bag, services etc that need to be removed. We needed a way to take the scan points and generate a high-quality, clean wireframe and outline.

“Our algorithm takes the points and generates a wireframe of the scan. The wireframe is more complex and uses tailored functions within the software to clean out as much noise and obstructions as possible. It eliminates much of the manual work.”

With the new technology, our users can import LAS files, choose the metadata options, modify them using a clipping box and remove points based on the value of the point such as intensity.

The tool was developed during the course of a year using feedback from various surveyors around the world. As a result, we have increased our ability to handle large data sets up to 200 million points in Deswik.CAD.

“The scanners generate massive amounts of data in a very short time period. The key was to take the large datasets and generate useful information for the operation without relying on manual processing. “If sites are scanning, once they have a *.LAS file they can import it into Deswik.CAD.”

The next stage, to be rolled out later this year, will look at introducing the software to open pit mines, with the technology already being piloted in South Africa by our Deswik survey team and other peer surveyors.

If you would like to find out more about Deswik.AdvSurvey, contact your nearest Deswik office.